BillO wrote:

Some of those chips are pretty big and running the cap over the chip diagonally may actually lengthen the distance from the power pins.

Leads have inductance, and you need to minimize the lead length in the bypass capacitors between the power pin and the ground pin, splicing on extra wire if necessary to make the span. Oh how I wish they had foreseen the future rising edge rates and clock speeds when they came up with pinouts, and put the power and ground pins in the middle of the IC not out at the corners! I have worked with more-modern ones that put a power and ground pin right together on each side of the IC, as close as possible to the die, ie, the actual silicon chip inside, to minimize inductance where it's most important to minimize.

You can still have bypass capacitors at the power rails too of course.

Quote:

They should design these things with the power rails between the dip leads (where the chanels are) and utilize a PCB base panel with power planes to distribute power to the solderless panels.

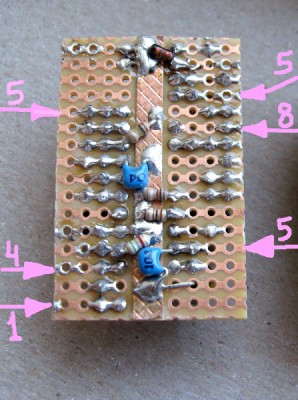

What I've often done with solder-type breadboards (which I use when there's a lot of analog circuitry involved) is to put adhesive copper foil down the middle for ground. Here's the idea, although this one is

purely analog (no digital), for work:

Attachment:

BBsigsSolderSide.jpg [ 94.69 KiB | Viewed 5745 times ]

BBsigsSolderSide.jpg [ 94.69 KiB | Viewed 5745 times ]

Most of the components are on the other side; but it became convenient and helpful to put some on the solder side. It works out particularly well for bypass capacitors, since the ground pin can go to the copper ground strip directly with a super-short connection, and the Vcc pin can just have a leadless chip capacitor soldered between its solder pad and the ground copper ground strip. There aren't any chip capacitors on this particular board, but it's not uncommon for me to put them on other boards.

Quote:

Another issue I'm dealing with is, even with power completely removed from the project I'm picking up 500mv peak to peak noise (the majority of what I'm measuring) between the power rails. I am under the belief this is coming from the LED lighting installed throughout the room I'm using. Has anyone else seen this? I'll earth the aluminum base to try to help with this.

50/60Hz mains frequency, or MHz stuff?

Quote:

One more question. It seems like solderless breadboards are not the hot setup for experimenting with anything above 1 or 2 MHz. What do the rest of you use when doing experiments at higher clock speeds and with faster devices?

Like cbmeeks said, wire-wrap or custom PCBs. The 6502 primer has a page answering wire-wrap questions and doubts, at

http://wilsonminesco.com/6502primer/WireWrap.html .