Joined: Fri Aug 30, 2002 1:09 am

Posts: 8432

Location: Southern California

|

In our company, I've always been pressed for maximum density. When we were doing stuff in thru-hole, I always made it so you almost can't see the board on the component side, because there's no space between components. You might not have any reason to go so dense; but if you want to, you can go a lot smaller than you're showing.

¼W resistors are less than .100" wide, and leaving .100" will be plenty. The label, "R21" for example, goes under the component, not beside it, as you mainly only need it when you're stuffing the board. If you want the reference designator for troubleshooting later, well, you have it on your CAD to look up on the screen. You could put the holes for a ¼W resistor as little as .300" apart (on centers); but for our production people, I always gave it .400". Hole size was .030", and pad size was .050". However, I only used ¼W in the rare case that a 1/8W resistor couldn't handle the power dissipation.

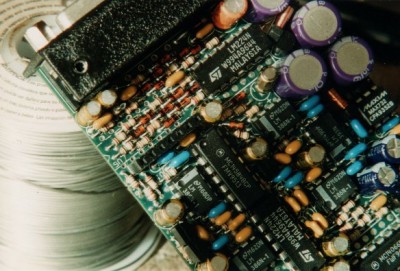

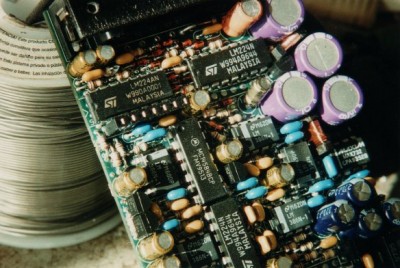

For 1/8W or 1/6W resistors, I put the hole spacing at .250", hole diameter .025", and pad width at .045". Leaving .075" width will always be enough; but if you stagger them like in the pictures below, you can go a lot closer. The two pictures are the same part of the same board (which was nearly all analog, not digital), showing how I put 11 resistors and diodes underneath each 14- or 16-pin DIP, staggered in five rows. The first pictures shows it before one of the ICs (in the top-left corner) was put over them, then the next picture shows it after the IC is installed over them.

Attachment:

denseNoU5.jpg [ 80.31 KiB | Viewed 902 times ]

denseNoU5.jpg [ 80.31 KiB | Viewed 902 times ]

Attachment:

denseWithU5.jpg [ 80.18 KiB | Viewed 902 times ]

denseWithU5.jpg [ 80.18 KiB | Viewed 902 times ]

(These are shown 2/3 of the way down the "Custom PCBs" page of the 6502 primer.)

The multilayer ceramic capacitors are sometimes available in .1" lead spacing, but I couldn't count on it, at least not back when we were doing this stuff; so I always went for .2" lead spacing. (Then we'd order .2" LS cap.s and what would come be .1's with the leads formed to fit into .2" spots! Grrrr.) The space I left for them was shaped like the racetrack around a football field, .270" long and .100" wide. The holes were .030" diameter and their pads were .050". We never had any production problems with these.

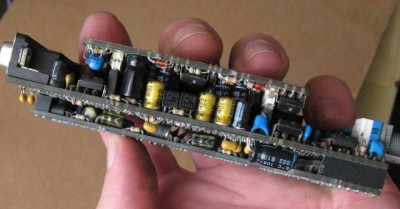

Here's the sandwich the above board went into. The whole thing went into a case hardly bigger than a bar of soap, and had about 500 components in it if it was ordered with all the options. (Actually the one shown is missing a board.)

Attachment:

244eSandwich.jpg [ 60.71 KiB | Viewed 902 times ]

244eSandwich.jpg [ 60.71 KiB | Viewed 902 times ]

Notice that with the mother board and the modules that plug into it on the top, the tall parts miss each other.

_________________ http://WilsonMinesCo.com/ lots of 6502 resources

The "second front page" is http://wilsonminesco.com/links.html .

What's an additional VIA among friends, anyhow?

|

|