banedon wrote:

I've started doing some wire wrapping, but have shortened the length of bare wire to about 0.5 inches due to the number of connections I need on a pin (I have 4 devices so need to connect 4 lots of wire to the the address/data bus pins).

You can daisychain for nearly everything, so a data bus pin for example seldom needs more than two wires on it, almost never more than three. Also, as discussed in the primer, the insulated part of the wire can go over a previous wrap so it doesn't take space on the pin, and then the wire comes down onto the pin when it reaches the stripped part.

Quote:

Also, I've noticed that when measuring resistance between each endpoint on a given wire-wrapped wire I get roughly 0.2 to 0.4 Ohms. Is this normal? I should be expecting absolute 0 Ohms?

I just measured a random bus connection on my workbench computer, a stretch of about 4" that goes from pin to pin to pin to pin, with three wires and six wraps; ie, the current had to go through six wraps to get from one end to the other. I don't even get 0.1 ohms which is the resolution of the DMM. So the average resistance of all the wraps is less than 0.01 ohms if the DMM rounds to the nearest 0.1 ohms. If you accounting for some resistance on the DMM's leads, it makes the WW look even better. These wraps BTW are also 22 years old.

Quote:

Also, is it a major no-no to use 1/2 inch rather than 1 inch bare wire or is it ok?

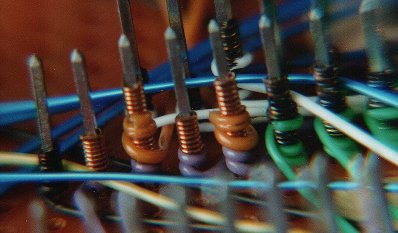

I would prefer at least 3/4". You want to make sure the turns between the ends have plenty of pressure kept on them. Make sure there's no gap between the turns, both to keep maximum pressure at the corners and so you can get the maximum number of turns and wires on a pin. Here again is one of the pictures on the WW page of the 6502 primer: